For fleet managers, fuel buyers, terminal operators, and sustainability leads staring down winter starts and warranty risk, cold flow gelling, filter plugging, and storage varnish aren’t “theoretical” problems—they sideline trucks, burn cash, and spike stress. You want diesel and biodiesel that actually behaves in January, that doesn’t oxidize into sludge by April, and that still clears engine certification. Off The Pump can help you thread that needle—advanced biodiesel formulation and blending, cold-flow & oxidative stability optimization, engine compatibility testing and certification, fleet transition planning and logistics, feedstock sourcing and sustainability auditing, plus life-cycle emissions analysis and carbon accounting—so you get reliable fuel without guesswork.

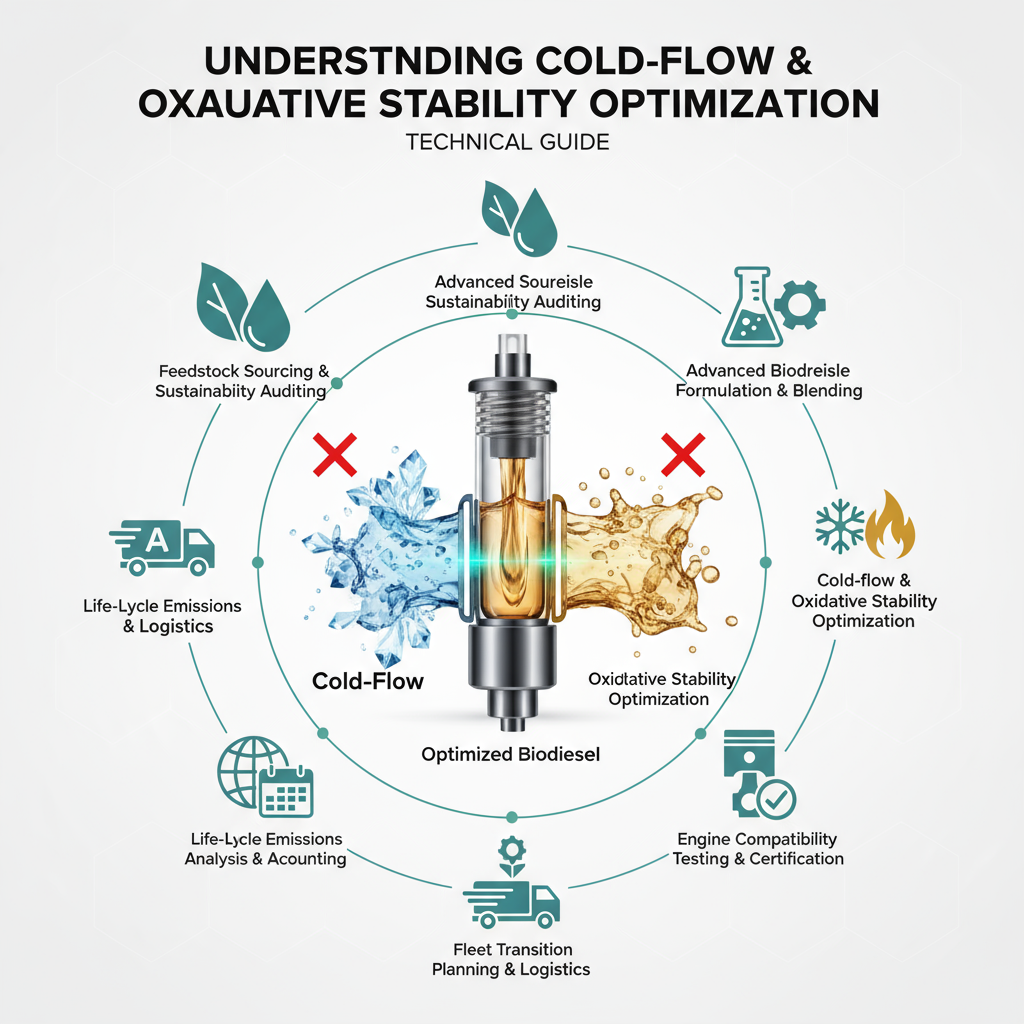

What is cold-flow & oxidative stability optimization?

Short version: it’s tuning fuel to stay pumpable and clean—low-temperature performance (CFPP, pour point, cloud point) and resistance to oxidation (Rancimat/induction time)—using smart blends, additives, and process controls.

Why do modern systems matter for biodiesel performance?

Because variability kills uptime. Modern systems blend on spec, adjust for feedstock shifts, and dose precise cold-flow improvers and antioxidants. Net-net: fewer filter plug events, better storage stability, smoother starts, and consistent compliance with OEM and ASTM/EN requirements.

Step-by-step: How to implement cold-flow & oxidative stability optimization

Define your operating envelope. Lowest site temps, altitude, storage turnover, return fuel temps, and warranty thresholds. Set targets for CFPP, pour point, and induction time. Simple, but essential.

Audit feedstocks and current fuel. Pull COAs and run confirmatory tests (cloud point, CFPP, Rancimat, acid number, metals). Layer in sustainability data. Off The Pump can handle feedstock sourcing and sustainability auditing.

Model blends and additives. Build a mini design-of-experiments: base ULSD + FAME profiles, renewable diesel, kerosene, cold-flow improvers, and antioxidants. Off The Pump’s advanced biodiesel formulation and blending speeds this—no expensive trial-and-error.

Lab-verify performance. Test cold flow (ASTM D6371/D2500/D97) and oxidative stability (EN 14112). Then run engine compatibility testing and certification—Off The Pump can coordinate—to de-risk injectors, aftertreatment, and seals.

Pilot in the field. Select 12–20 vehicles/routes (cold spots, stop‑and‑go, overnights). Track start quality, filter ΔP, water contamination, and fuel turnover. I’ve seen tiny tweaks here save weeks of headaches.

Operationalize and monitor. Create seasonal blend schedules, tank prep SOPs, and additive logistics. Set alerts on CFPP drift and induction time. Off The Pump supports fleet transition planning and logistics—and ongoing carbon accounting.

Benefits you can expect

- Reliable winter starts—fewer cold-flow surprises during polar vortex snaps.

- Longer storage stability—less gum, fewer filter swaps, cleaner injectors.

- Engine peace of mind—data-backed compatibility and certification.

- Lower total cost—less downtime, optimized additive spend, smarter blending.

- Stronger ESG—feedstock traceability plus life-cycle emissions analysis that actually holds up to audits.

Is this compatible with my engines?

Yes—if you prove it. That means lab fuel property targets matched to OEM specs, plus engine compatibility testing and certification before full rollout. If this feels overwhelming, Off The Pump can run the testing, dial the blend, and hand you a clean, cert-ready playbook.

What’s the quick start?

Grab last winter’s failure points, your coldest 10-day window, and current COAs. Then ask for a targeted blend-and-additive matrix. Honestly, that small upfront test—done right—pays for itself before the first freeze… and keeps paying all season.