For fleet operators, fuel engineers, and sustainability leads who need diesel performance without surprises, the biggest headaches show up fast: winter gelling, filter plugging at 3 a.m., uncertain OEM positions on blends, and auditors asking for carbon data yesterday. You want proven supply, real test data, and a rollout plan that won’t strand trucks—or budgets. Off The Pump brings advanced biodiesel formulation and blending expertise—backed by cold-flow & oxidative stability optimization, engine compatibility testing and certification, and practical field support—so you can move to lower-carbon fuel with confidence, not crossed fingers.

What is advanced biodiesel formulation and blending?

It’s the science of combining specific feedstocks, additives, and blend ratios (B5, B20, B30, B50, B100) to hit targets like cetane, lubricity, CFPP, oxidative stability, and emissions—consistently. Think of it like tuning a powertrain, but for fuel molecules. In my experience, the best results come from pairing used cooking oil biodiesel with selective winterization, antioxidants, and precise petroleum diesel co-blending to meet ASTM D7467 or EN 16734 every single load.

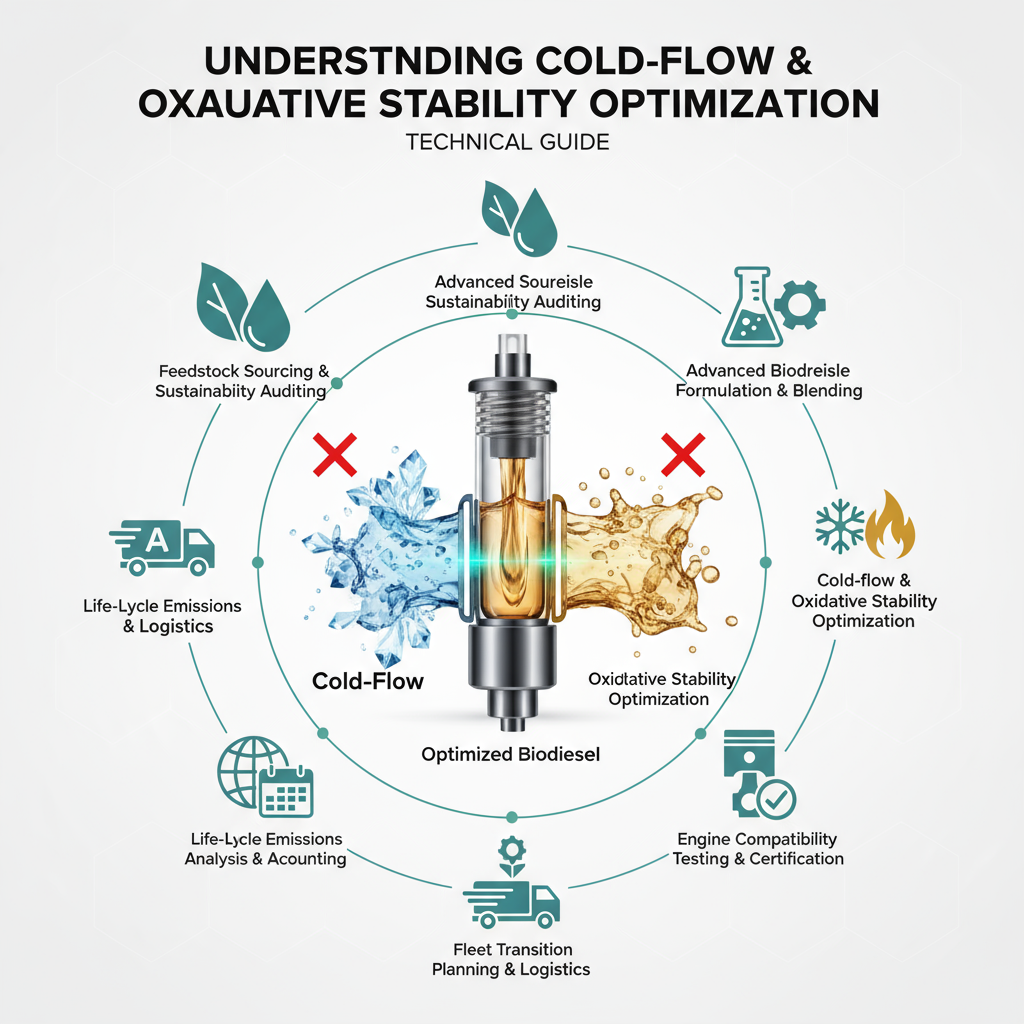

How do you optimize cold-flow and oxidative stability without sacrificing performance?

Cold-flow & oxidative stability optimization hinges on three levers: feedstock choice, process treatment, and additive chemistry. Why? Because crystal formation and peroxide growth follow different kinetics.

Cold-flow: set a hard CFPP goal by geography—say −12°C for Chicago in January—then engineer backwards. Use higher-unsaturation feedstocks (UCO), fractionate out high-melting methyl esters, dose a modern PPD (200–600 ppm), and spec low-wax ULSD partners. Always confirm with CFPP, cloud point, and LTFT testing, not just a pour point guess.

Oxidative stability: hit ≥8 h Rancimat at 110°C with phenolic antioxidants (BHT/BHA blends), control metals (copper strips are the silent killer), dry to water ≤500 ppm, and cap headspace oxygen in storage. Simple, but unforgiving. We verify with repeat Rancimat and insolubles—no cut corners.

Will it run in my engines without warranty drama?

Short answer: yes, if you respect standards and the OEM’s line. Most on-road engines in North America accept up to B20 under ASTM D7467; many Euro OEMs certify B30 for captive fleets. The proof lives in engine compatibility testing and certification: elastomer swell checks, injector coking, HFRR lubricity, and durability cycles. Off The Pump packages the paperwork—COAs, blend tickets, and OEM position letters—so service managers don’t have to play detective.

What does fleet transition planning and logistics include?

Real talk: the technical fuel is the easy part—the handoff is where things break. Fleet transition planning and logistics cover tank cleaning, water management, filter right-sizing, seasonal blend swaps (B20 to B5 ahead of deep cold), on-site splash vs. rack-blend choices, driver comms, and a stepped adoption (B5 → B10 → B20 over 30–60 days). If this feels overwhelming, Off The Pump can handle it for you—design to first delivery—so operations hit the ground running.

How do you vet feedstock sourcing and sustainability auditing?

Feedstock sourcing and sustainability auditing means traceable supply, period. We qualify ISCC-certified UCO and tallow, validate RFS D-codes, audit chain-of-custody, and screen ILUC-sensitive claims. I’ve noticed the strongest programs keep supplier variability under 10% month-to-month and lock additive baselines, which keeps fuel specs—and carbon intensity—predictable.

How is life-cycle emissions analysis and carbon accounting done?

Use a defensible model (GREET 2024), express results in gCO2e/MJ, and tie every gallon to evidence. Example: ULSD baseline ~94 gCO2e/MJ. A UCO biodiesel at 24 gCO2e/MJ blended as B20 yields 80 gCO2e/MJ—about a 15% reduction. For a fleet of 87 trucks burning 1,200,000 gallons/year at 128 MJ/gal, that’s roughly 2,150 metric tons CO2e avoided. We align this with Scope 1 reporting, attach CI scores per batch, and—where applicable—map to LCFS/CFP credits. Dollars matter: even with a $0.12/gal premium, net program value can go positive with credits and ESG targets hit.

Seasonal prep and storage basics—what should I do before winter?

Look, heading into winter 2025, don’t gamble. Set a winter-grade spec with a defined CFPP buffer (target 5°C below your 10th percentile ambient), polish tanks, drain water bottoms weekly, keep filters warm, and lock a B5 contingency for arctic snaps. And always pull retains—if something drifts, you’ll know exactly why… and fix it fast with data, not guesswork.