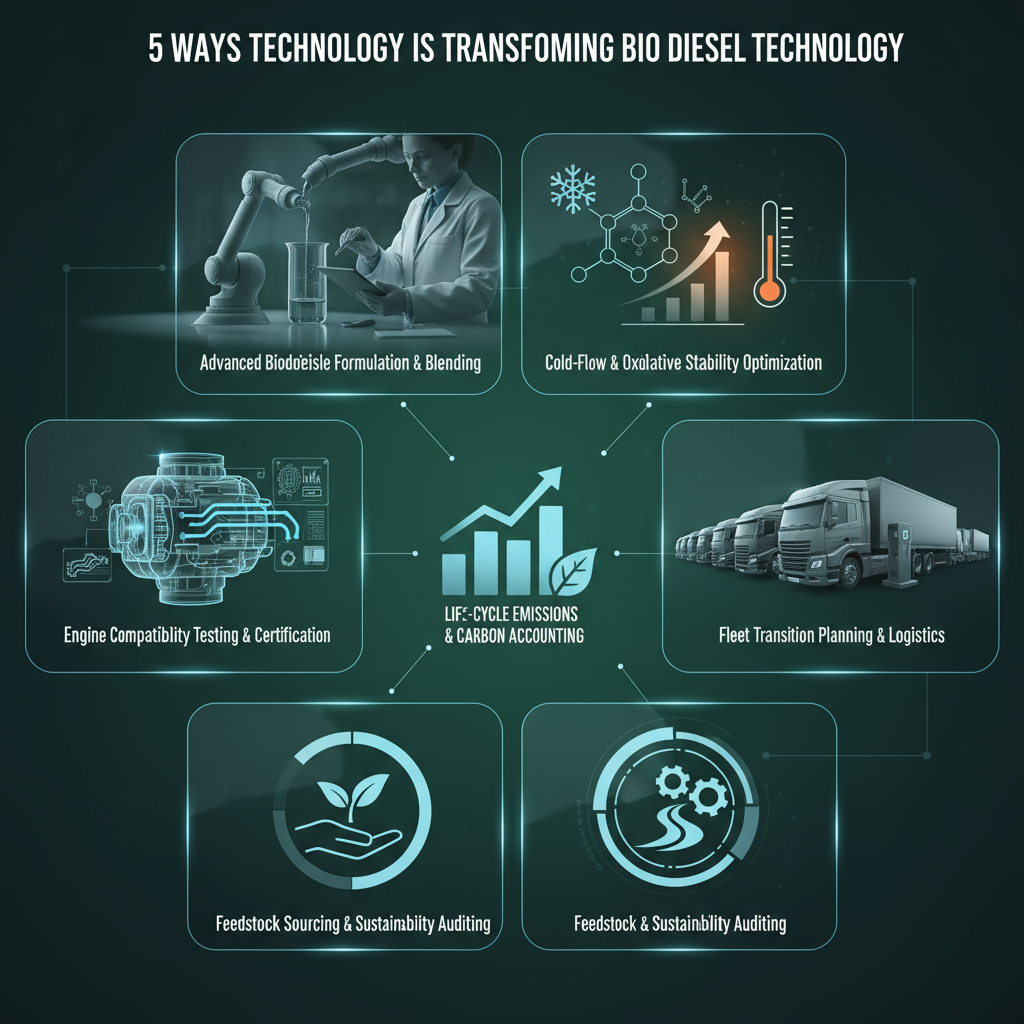

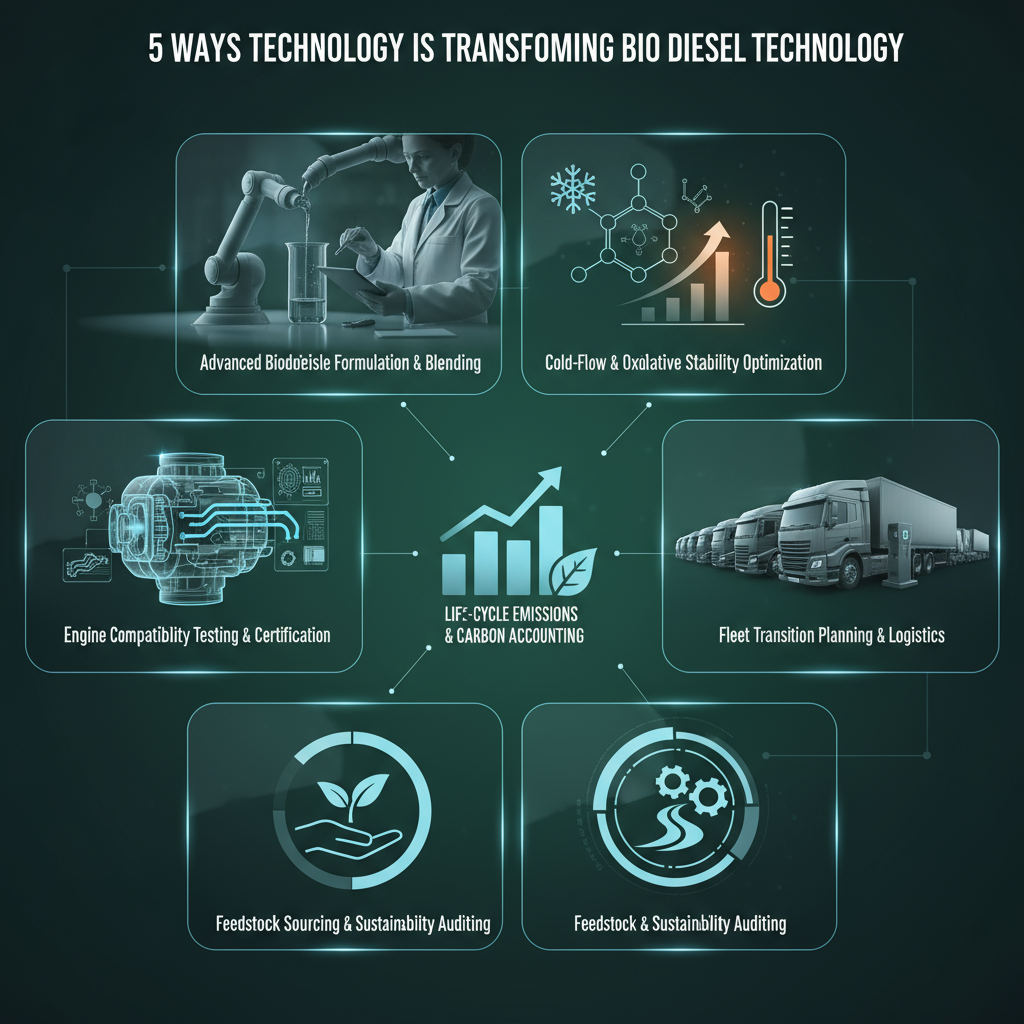

If you’re a fleet operator, fuel distributor, plant manager, or sustainability lead, this is for you. You’re juggling blend quality, winter gelling, warranty worries, scattered depots, messy feedstock claims, and carbon reporting that eats your Fridays—been there, seen the scramble before January cold snaps. Off The Pump steps in with advanced biodiesel formulation and blending, cold-flow & oxidative stability optimization, and engine compatibility testing and certification—plus practical help with fleet transition planning and logistics, feedstock sourcing and sustainability auditing, and life-cycle emissions analysis and carbon accounting. Not hype—just proven workflows so you hit targets without drama.

How is technology transforming biodiesel right now?

Short answer: smarter data and faster validation. Think inline analytics, predictive stability, hardware-in-the-loop engines, digital twins for depots, and auditable carbon math. It’s tangible—less guesswork, more uptime.

Step 1: Advanced biodiesel formulation and blending — how do you lock in consistent fuel?

Start by digitizing your spec: cetane, density, CFPP target, oxidative stability hours, metals. Then use inline NIR and mass-flow controllers to blend precisely—no “close enough” batches. Build an additive recipe that’s traceable by lot and treat rate, log it automatically, and verify against ASTM methods before release. I’ve noticed that capturing every tweak (even 40 ppm antioxidant shifts) saves headaches later during audits. If this feels overwhelming, Off The Pump models blend permutations, runs rapid bench screens, and hands you a validated, repeatable playbook.

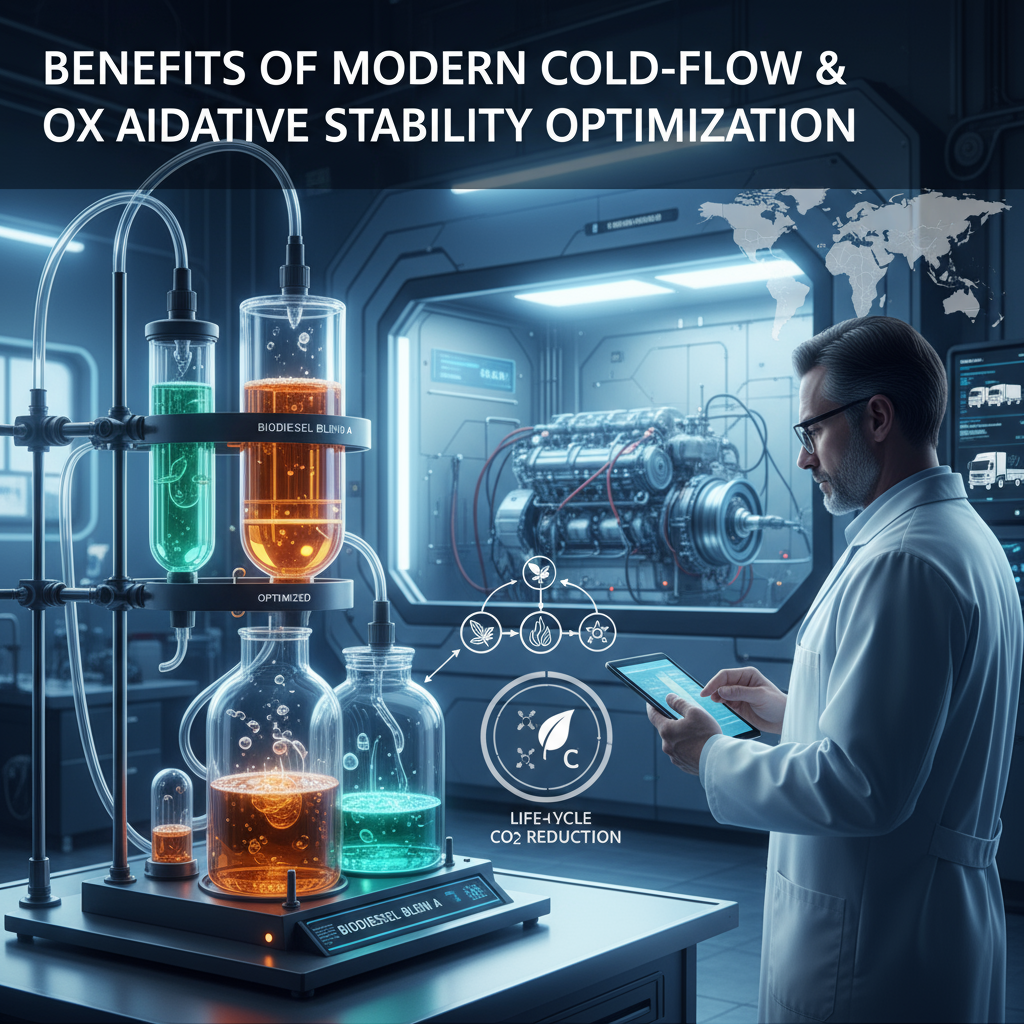

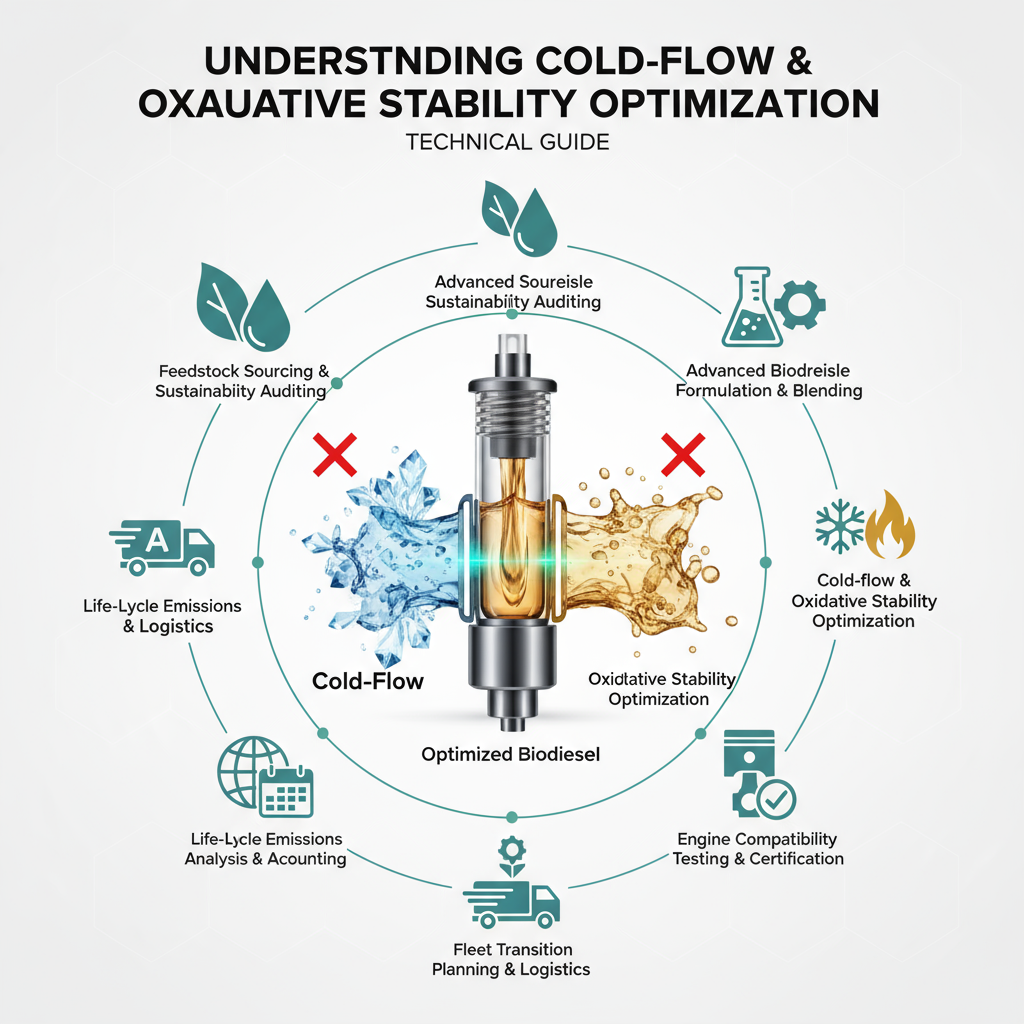

Step 2: Cold-flow & oxidative stability optimization — how do you prevent gelling and varnish?

Target the environment you actually operate in—lowest overnight ambient, not daytime highs. Use cold-flow improvers sized to cloud point and CFPP, then confirm with lab CFPP and pour point, not just a hunch. For storage, extend Rancimat stability with the right antioxidant package and keep moisture out—real talk, water undoes half the good work. Before winter, switch to a winter blend cutover date, sample tanks weekly, and track filter ΔP so you catch issues early. Off The Pump pairs lab screens with small-batch field pilots so you don’t learn the hard way during a polar vortex.

Step 3: Engine compatibility testing and certification — will your fuel protect warranties?

Map your engine families and duty cycles, then run hardware-in-the-loop plus dyno durability on representative platforms. Validate to ASTM D7467 or OEM-specific specs, measure injector coking, filter plugging tendency, deposits, and emissions with DPF load insights. Why? Because documented Engine compatibility testing and certification moves you from “should work” to “approved for use.” Off The Pump’s protocol shortens time to sign-off and extracts the data your OEMs actually care about.

Step 4: Fleet transition planning and logistics — what’s the smoothest rollout?

Baseline routes, temps, and idle time, then pilot one depot for 30 days at B5 or B20 with telemetry on fuel economy and maintenance tickets. Clean tanks first (don’t cut corners), keep spare filters on-site, and set reorder points based on real burn rates. Train drivers and techs—five minutes on cold starts, microbial control, and housekeeping avoids 87 avoidable callouts. Off The Pump builds a depot-by-depot plan, simulates inventory turns, and automates changeovers so you scale without surprises.

Step 5: Feedstock sourcing & sustainability auditing + life-cycle emissions analysis and carbon accounting — how do you prove and improve CI?

Stand up traceability from aggregator to esterification with supplier attestations, geo-tags, and periodic audits—Feedstock sourcing and sustainability auditing should be verifiable, not vibes. Then calculate CI with a transparent model and assumptions, run sensitivity on transport distances and energy sources, and document continuous improvements. Life-cycle emissions analysis and carbon accounting let you capture LCFS or internal carbon benefits without compliance heartburn. Off The Pump sets up auditable data flows, aligns to accepted models, and gives you board-ready reporting.

Quick answers people ask

Does biodiesel void engine warranties?

No—use OEM-approved blends (often up to B20 under ASTM D7467) and keep documentation from your testing. That’s the coverage your service manager wants to see.

What blend is best in winter?

Use a properly treated B5–B20 designed for your local minima; confirm with CFPP tests and real-world starts. And switch before the first hard freeze… not after.