For fleet managers, fuel buyers, and sustainability leads evaluating low‑carbon liquid fuels, the pain is real: cold‑weather gelling, warranty anxiety, inconsistent feedstock quality, and auditors asking for life‑cycle receipts you don’t have yet. You need real performance, not marketing—engines that start at 5 a.m., clear carbon numbers, and logistics that don’t disrupt routes. Off The Pump helps you do exactly that through advanced biodiesel formulation and blending, cold‑flow & oxidative stability optimization, and engine compatibility testing and certification—practical, lab‑backed, field‑proven support without the hype.

How do you select the best advanced biodiesel formulation and blending solution?

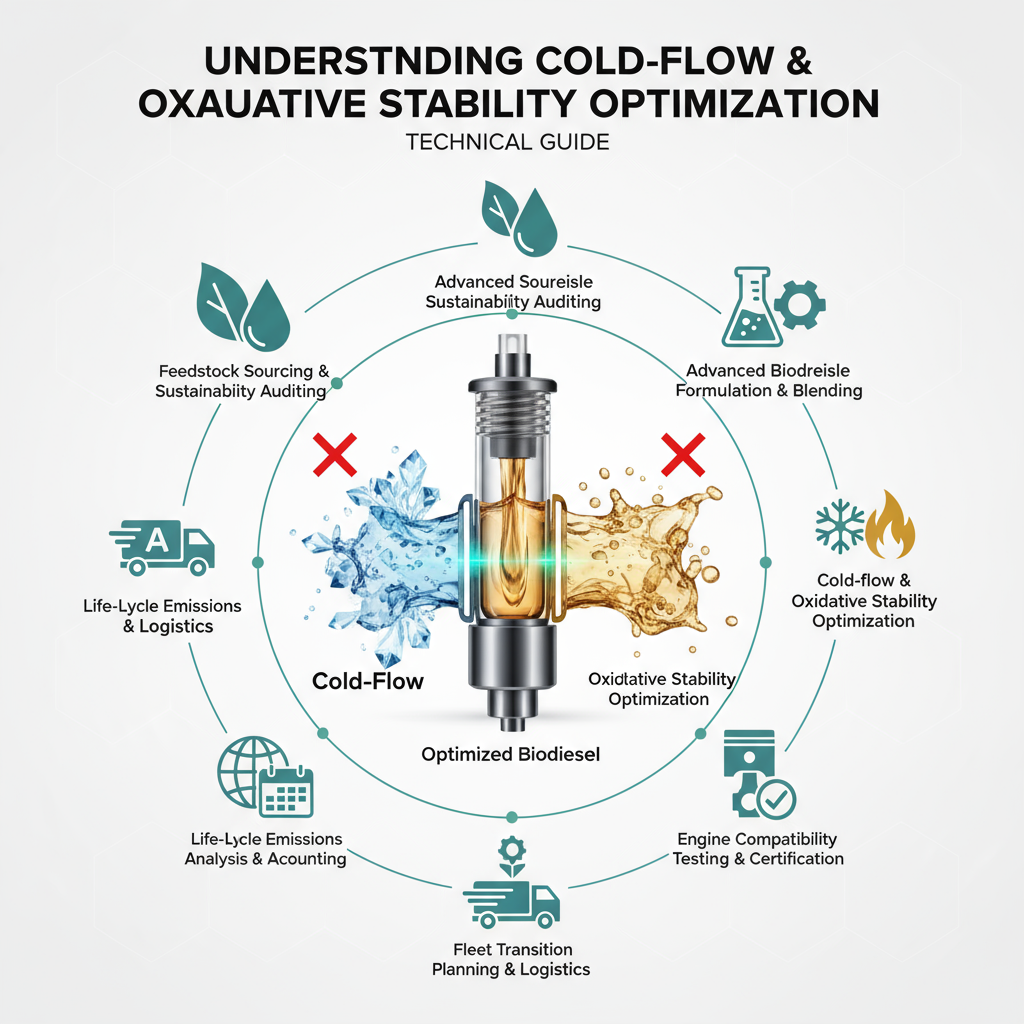

1) Cold‑flow & oxidative stability optimization — what should you demand?

Ask for data, not promises: CFPP/pour point targets by season (e.g., CFPP ≤ −12°C for winter), additive packages tailored to your actual feedstocks, and EN 14112/Rancimat hours for oxidation stability. I’ve seen fleets avoid dozens of cold‑start calls just by tweaking kerosene cuts and antioxidants—small changes, big wins.

2) Engine compatibility testing and certification — how do you protect warranties?

You want ASTM D7467 (B6–B20) and D6751 compliance, OEM TSB alignment, and on‑road validation on your engines, not someone else’s. Look for dynamometer and field trials with fuel system inspections and injector deposits measured. Off The Pump can run that testing and document it—so warranty conversations stay calm.

3) Feedstock sourcing & sustainability auditing — how do you verify quality and ESG?

Require traceable feedstocks (UCO, tallow, or high‑spec soy), ISCC/RSB certifications, and COAs for every batch. No mystery blends. Off The Pump’s sustainability auditing checks chain‑of‑custody and flags instability risks before they hit your tanks.

4) Life‑cycle emissions analysis & carbon accounting — what counts, literally?

Insist on GREET‑based life‑cycle emissions analysis with clear co‑product credits and transport assumptions. You need auditable kg CO₂e per gallon and route‑level reporting. If this feels overwhelming, Off The Pump can handle the modeling and hand you auditor‑ready files.

5) Blend design & seasonal strategy — what’s the right BXX for your climate?

Summer might run B30–B50 for deeper carbon cuts; winter often shifts to B10–B20 with cold‑flow additives. The best part is—well, there are two: predictable starts and predictable emissions. Build a calendar now; don’t wait for the first cold snap.

6) Fleet transition planning & logistics — how do you roll out without downtime?

Map sites, tank conditions, and delivery windows. Schedule tank cleaning, filter changes, and pilot routes first (10–15 vehicles). Off The Pump orchestrates the rollout—procurement, carriers, and site commissioning—so operations keep humming.

7) On‑site QA/QC & data reporting — what KPIs prove it works?

Set hard gates: water & sediment, acid number, metals, and stability on receipt; weekly CFPP spot checks in winter; fuel economy and regen frequency by asset. I think live dashboards change behavior—drivers trust what they can see.

8) Cost, hedging, and incentives — how do you make the economics pencil?

Stack LCFS/RIN credits, state rebates, and procurement terms (price caps, index‑minus). I’ve noticed fleets save real money by locking additized winter product early—February uptime beats emergency tows that cost an arm and a leg.

Quick answers people ask

What blend level should I choose—B20, B50, or B100?

B20 is the easiest warranty/ops starting point; B30–B50 boosts carbon cuts in warm months; B100 works with the right engines, heaters, and controls. Off The Pump models this by route temps and duty cycles, then sets a seasonal playbook.

Will biodiesel void engine warranties?

No—if you use spec fuel and follow OEM limits. Keep ASTM certificates and service records. Off The Pump’s engine compatibility testing and certification packages make this crystal clear for OEMs.

How do I avoid winter gelling?

Blend appropriately (often B10–B20), dose cold‑flow additives, manage tank housekeeping, and verify CFPP before delivery. Simple, and really effective.