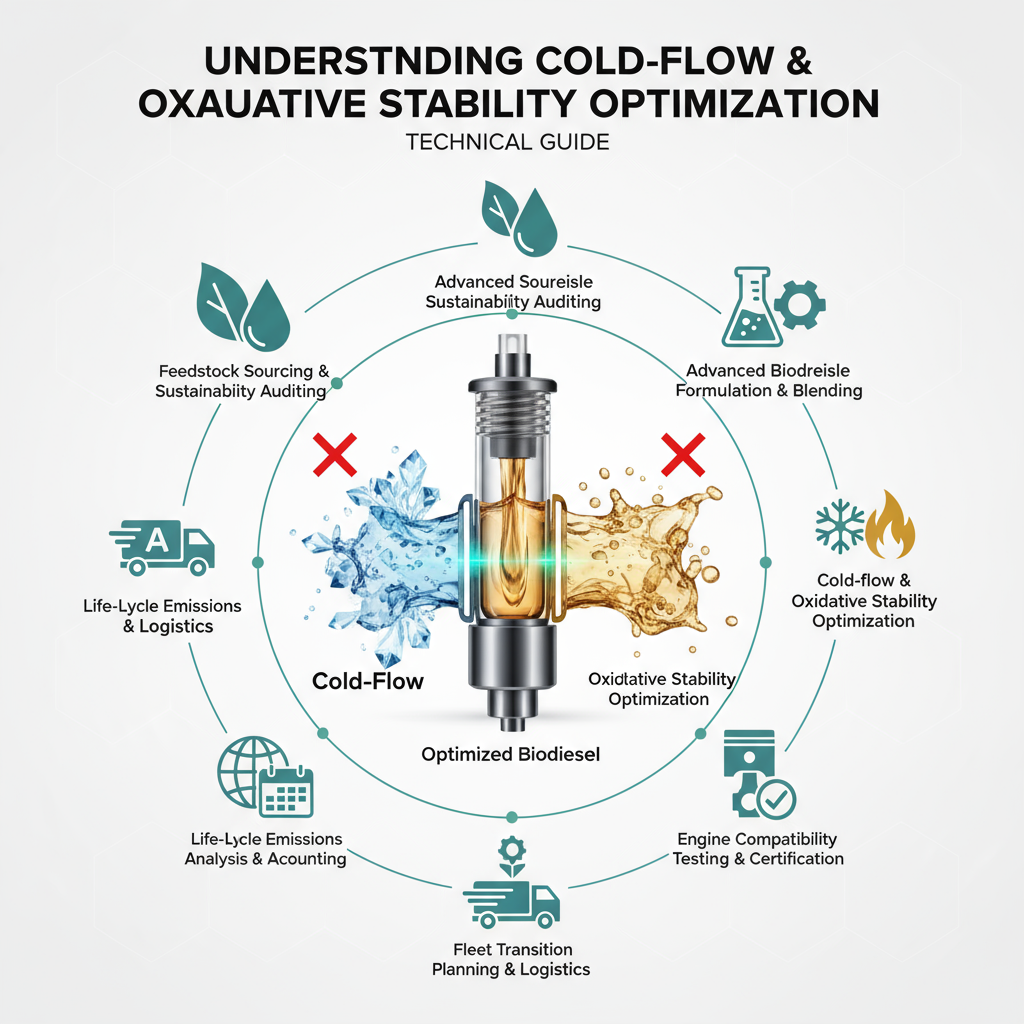

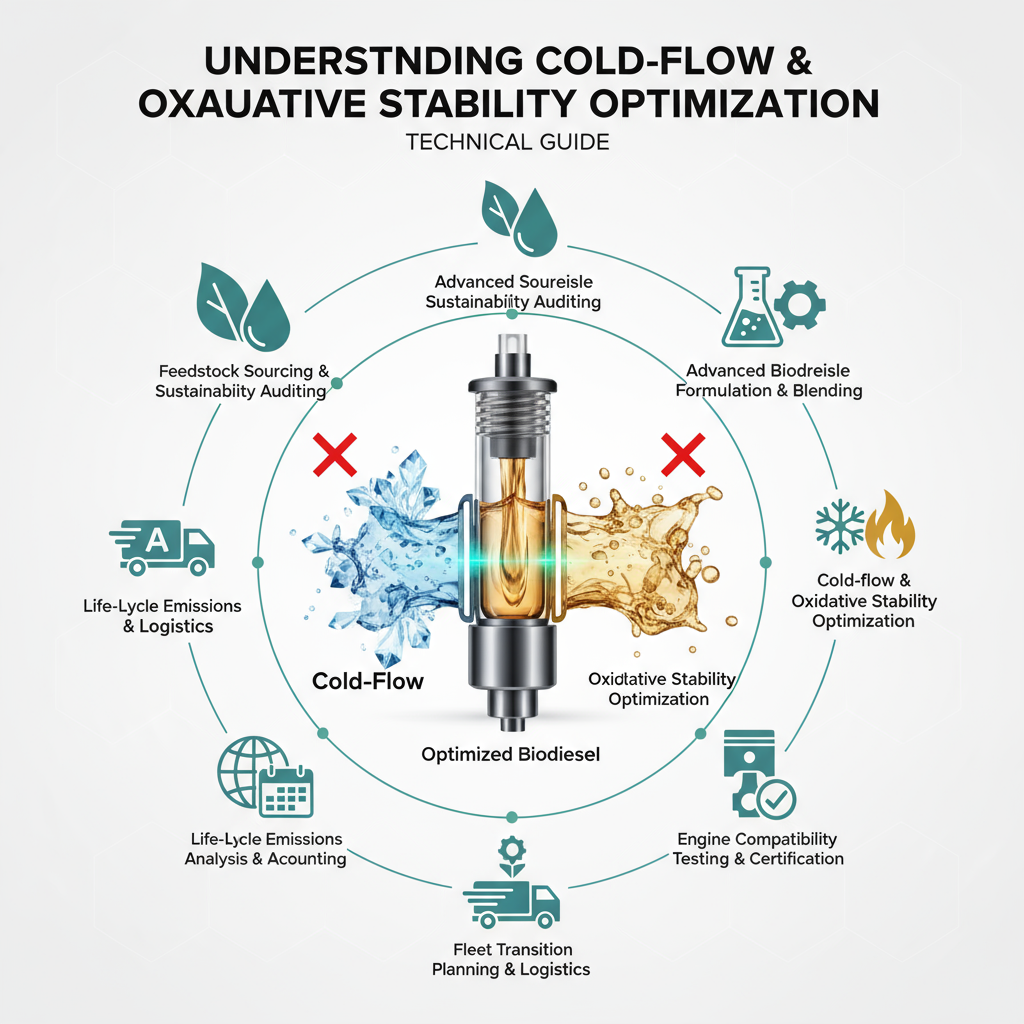

For fleet operators, fuel buyers, and sustainability managers who need biodiesel that actually performs in real winter and under warranty pressure—this guide is for you. You’re juggling cold starts, filter plugging, storage hiccups, and the very real fear of engine claims while you still have to hit emissions targets and budgets. Off The Pump plugs that gap with hands-on expertise in Advanced biodiesel formulation and blending, Cold-flow & oxidative stability optimization, and Engine compatibility testing and certification—so you keep uptime high and headaches low (I’ve seen too many programs stall over tiny details).

What is “cold-flow” in biodiesel and why does it matter?

Cold-flow refers to a fuel’s behavior at low temperatures—cloud point, pour point, and CFPP (cold filter plugging point). As temps drop, crystals form and clog filters. That’s how roadside calls happen at 4 a.m. The goal is simple: push CFPP lower than your lowest expected ambient. For winter routes, I recommend a documented 5°C safety margin—no guessing, no towing.

How can I improve cold-flow without sacrificing engine protection?

Two levers: formulation and logistics.

- Use Advanced biodiesel formulation and blending: pick lower-saturate feedstocks, blend with ULSD or renewable diesel, and dose a proven cold-flow improver—8°C CFPP improvement is common in controlled programs.

- Winterization and filtration: chill-filter to remove higher-melting species, then re-test CFPP (don’t skip the re-test).

- Additive strategy: combine nucleators + polymer CFI; dose by lab curve, not a one-size shot.

- Tanks matter: keep water out, insulate exposed lines, circulate fuel on idle weekends.

If this feels like a lot, Off The Pump can design the recipe, validate it in the lab, then prove it in engines—so you get performance and warranty alignment.

What drives oxidative stability—and how do I stabilize biodiesel?

Oxidation is accelerated by polyunsaturation, heat, oxygen, metals, and long storage. Unchecked, you get acids, gums, and injectors that look like they ran tar. Targets: ASTM D6751 with Rancimat ≥ 3 hours; EN 14214 at ≥ 8 hours for export specs. How to hit them?

- Antioxidants (e.g., TBHQ or approved phenolics) added early—right after transesterification is ideal.

- Metal deactivators to neutralize trace Cu/Fe from pumps and tanks.

- Oxygen control: tight seals, nitrogen blanketing for bulk, cooler storage, first-in-first-out within 90 days.

- Feedstock choice matters: tallow boosts cold soak risk; soy can oxidize faster—so you balance with additives and process polish.

Off The Pump tunes stability packages to your exact feedstock mix and storage profile, then verifies with accelerated aging so real-world months don’t surprise you.

Which tests prove cold-flow and stability—and are engines covered?

Cold-flow: ASTM D6371 (CFPP), D2500 (cloud point), D97 (pour point), plus cold soak filtration (CSFT). Oxidation: EN 14112 (Rancimat), ASTM D7545 (Rapid OX), and ASTM D2274 (storage stability). Now the big question—will engines accept it? That’s where Engine compatibility testing and certification enters: OEM spec mapping, elastomer swell checks, injector spray pattern verification, and on-vehicle pilots. Off The Pump documents results so your suppliers, OEMs, and insurers are aligned.

Does feedstock sourcing change the optimization plan?

Yes—dramatically. UCO and canola help cold-flow; animal fats help cetane but raise cold soak and saturation. The smart play is tying formulation to Feedstock sourcing and sustainability auditing, then modeling Life-cycle emissions analysis and carbon accounting so your blend hits both performance and ESG. I think the winning combo is transparent supply + tuned additives + certified testing—no corners cut.

What’s a practical rollout plan for fleets this winter?

Simple, stepwise, and documented. And fast.

- Pilot: 30-day trial on 12 vehicles with baseline/weekly CFPP, CSFT, and fuel-water checks.

- Blend ladder: B10 to B20 (or B30 with renewable diesel) once data is clean for 14 consecutive days.

- Preventive maintenance: clean tanks, stage 10 extra filters per 50,000 gallons, log differential pressure.

- Cold playbook: switch to winter cut by November 1, dose CFI at receipt, verify CFPP at -20°C if routes see -15°C lows.

- Reporting: roll up fuel KPIs with Life-cycle emissions analysis for leadership.

Take Sarah—fleet manager in Denver—who saved $4,200 in road calls last January by locking in a pre-tested blend and a filter-change schedule. Off The Pump handled Fleet transition planning and logistics so her team could, you know, drive. Real talk: that’s the goal.