What is Biodiesel? From Cooking Oil to Fuel

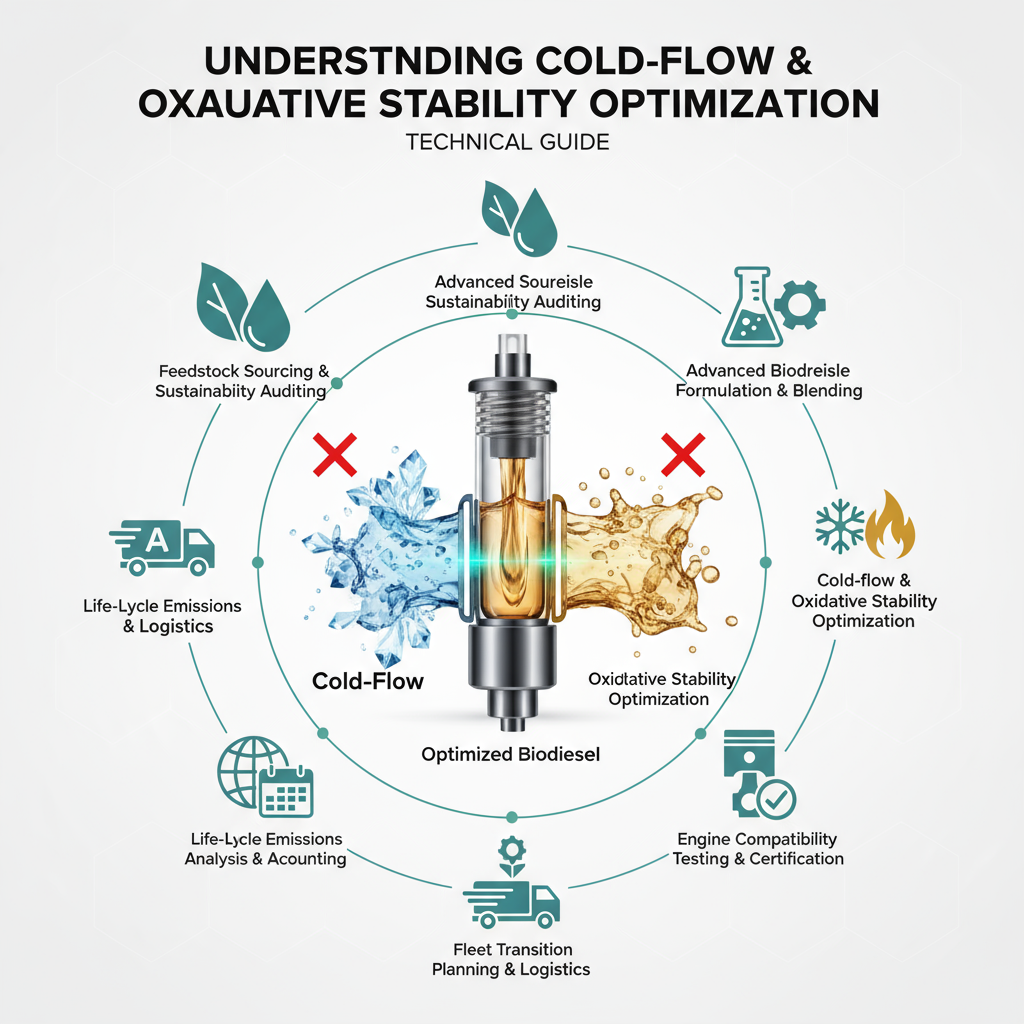

This guide is for diesel vehicle owners, fleet managers, and sustainability leads who keep asking if you can fuel a car with cooking oil, if bio diesel will hurt your engine, or how to switch without chaos. Fuel bills feel high, specs are murky, winter gelling is scary, and nobody wants warranty drama or downtime. Off The Pump helps you cut through the noise—advanced biodiesel formulation and blending, engine compatibility testing, cold-flow optimization, carbon analysis, even feedstock sourcing—so you can roll out bio diesel confidently, not experimentally.

what is bio diesel

Bio diesel is a renewable diesel fuel made from fats and oils—think used cooking oil, soybean oil, or animal fats—chemically converted into fatty acid methyl esters (FAME) via transesterification. In plain English: you take an oil, react it with methanol and a catalyst, separate the glycerin, and you’re left with biodiesel that can blend with petrodiesel. Common blends are B5 (5% biodiesel), B20 (20% biodiesel), and B100 (100% biodiesel).

Why do people use it? Lower life-cycle CO₂ (many fleets see 50–80% reductions depending on feedstock), better lubricity than petrodiesel, and a straightforward path to decarbonize existing diesel engines. It’s not perfect—slightly lower energy content than petrodiesel, different cold-flow behavior, and it can clean residue from tanks (which can clog filters early on)—but for fleets that plan well, it’s a lever that works.

Can you really fuel a car with cooking oil?

Short answer: not directly. You can’t just pour fryer oil into a modern diesel and call it a day. Why? Because straight vegetable oil (SVO) is too viscous and doesn’t combust cleanly in stock engines. You either convert the oil into biodiesel or install a dedicated SVO conversion system with heating and switching—two very different paths.

For most drivers and fleets, converting oil to biodiesel is the practical route. It yields a fuel that meets ASTM D6751 specs and can be blended into regular diesel. Also, taxes, permits, and ASTM quality standards matter if you sell or run it commercially. If this feels like a lot, Off The Pump can handle the feedstock sourcing, quality control, and certification—so you don’t have to play chemist or lawyer.

Biodiesel vs diesel: what actually changes?

Biodiesel fuel vs diesel, here’s the quick comparison. Biodiesel has about 8–10% less energy per gallon than petrodiesel, so B20 might show a roughly 1–2% drop in mpg—often barely noticeable in real-world driving. Cetane is typically comparable or higher, and lubricity is better (nice for pumps and injectors). Emissions shift: lower particulate matter and CO, but NOx can tick up without proper calibration or additives.

Storage and cold flow are where people get tripped up. Biodiesel can oxidize faster and gel sooner than petrodiesel if it’s not formulated right. That’s why you’ll see winterized blends, cold-flow improvers, and anti-gel programs. Some folks even say “coat diesel” when they mean anti-gel treated diesel—same idea: keep it flowing. Off The Pump designs blends for your climate—testing stability, managing water, dialing in additives—so your trucks start on that first crank in January.

how to make bio diesel

The safe, legal process is called transesterification. In essence, you clean your oil, react it, then clean the fuel. Here’s the high-level, actionable flow:

- Collect and pre-treat feedstock: filter particulates and remove water. Dirty, wet oil wrecks yields and soap formation.

- Test and titrate: determine free fatty acids to set catalyst dose (sodium or potassium hydroxide). This is the difference between a clean reaction and a gummy mess.

- React with methanol and catalyst: form sodium methoxide or potassium methoxide, mix with warm oil, allow reaction to proceed. It’s chemistry, not vibes—measure precisely.

- Separate and wash: glycerin settles out; wash biodiesel to remove soaps, residual methanol, and catalyst, then dry thoroughly.

- Verify quality: check for water, glycerin, viscosity, acid number, and cold properties. Target ASTM D6751 before using or selling.

Important safety note: methanol is flammable and toxic; lye is caustic; vapors need proper ventilation. Permits and fuel taxes apply. If you’d rather not build a mini refinery in your garage, Off The Pump can produce, test, and certify bio diesel for you—or set up a compliant program, start to finish.

can i use bio diesel in my truck

Yes—most modern diesel trucks can run B5 without any special steps, and many are approved up to B20. Check your owner’s manual and look for the B20 badge or official guidance. If your truck is older (think pre-2007 era), watch for natural rubber components that may soften with high blends; modern trucks use compatible materials.

Practical tips from the field: swap your fuel filter after the first couple of tanks if you’re moving to B20—bio diesel’s solvent effect can clean your tank and send loosened deposits into the filter. In cold climates, choose seasonally appropriate blends and additives, store fuel dry, and monitor for microbial growth if you have bulk tanks. DPF/SCR systems generally tolerate B20 well when the fuel meets spec; poor-quality fuel is what causes headaches. Off The Pump performs engine compatibility testing and cold-flow optimization, so your warranty and uptime stay intact.

can i use bio diesel

You can, but pick the right blend for your climate and vehicle, and make sure the fuel meets ASTM D6751 and your OEM’s guidelines. Fleets usually standardize on B5–B20 with seasonal adjustments—simple and effective.

can i use bio diesel in my car

If you drive a light-duty diesel car, many OEMs allow up to B20 in certain models, while some specify B5. Always check the fuel door and manual. I’ve seen drivers run B20 for 87,000 miles without an issue—because the fuel met spec and they stayed on top of filters. If in doubt, start with B5, monitor, and scale up.

Fuel a car with cooking oil: myth vs method

People search “fuel car with cooking oil” a lot. The real path: convert that oil into biodiesel or use a purpose-built SVO system. Pouring fryer oil straight into a common-rail diesel? Bad idea—poor atomization, carbon buildup, and potential injector damage. Off The Pump can assess your goals, route you to compliant biodiesel, and even audit feedstock sustainability so your emissions reductions are real, not just marketing.

Where Off The Pump helps you win

If you want bio diesel to just work—no guesswork—lean on experts. Off The Pump handles advanced biodiesel formulation and blending, engine compatibility testing and certification, cold-flow and stability optimization, life-cycle emissions analysis and carbon accounting, fleet transition planning and logistics, and feedstock sourcing with sustainability auditing. And if your roadmap includes renewable biogas, we capture and upgrade it too—so you can decarbonize both liquid and gaseous fuels in one strategy.

FAQ

Does biodiesel void my warranty?

Using blends within your OEM’s approved limit (often B5 or B20) and meeting ASTM D6751 won’t void warranties. Problems arise from off-spec fuel. Off The Pump supplies certified blends and documentation to keep compliance bulletproof.

Will biodiesel gel in winter?

All diesel can gel if it’s cold enough. Biodiesel has a higher cloud/CFPP, so use winterized blends, anti-gel additives, and proper storage. If you’ve heard “coat diesel” for winter diesel, that’s basically anti-gel treatment—same concept. We tailor cold-flow packages by region and season.

Is biodiesel cheaper than diesel?

Sometimes yes, sometimes no—it depends on feedstock prices and credits. The bigger value is emissions reduction and compliance. Many fleets offset costs through LCFS/RINs and smart sourcing. Off The Pump models total cost of ownership and carbon so you see the full picture.

Can biodiesel be used in generators and off-road equipment?

Yes. B5–B20 works well in most compression-ignition equipment. Verify manufacturer limits, winterize as needed, and keep tanks dry and clean. We can set specs by application—gen-sets, marine, construction—so performance is predictable.

How do I start without disrupting operations?

Begin with B5 across the fleet, monitor filters and telematics, then step to B20 where approved. Schedule winter blends early, train drivers, document results. Off The Pump can run a pilot, certify fuels, and roll out logistics so you hit the ground running—smoothly.