For fleet managers, sustainability officers, and community health advocates who want real progress on clean energy, this is for you — you're frustrated by air pollution, rising compliance costs, and greenwashing that promises more than it delivers. Our team helps by evaluating biodiesel options, running lifecycle carbon and health impact analyses, and guiding on fuel sourcing and engine compatibility with practical, data-backed plans you can implement without guesswork.

What is biodiesel and how is it different from regular diesel?

Biodiesel is a renewable fuel made from biological sources like vegetable oils, animal fats, or used cooking oil, processed through a chemical reaction called transesterification to produce fatty acid methyl esters (FAME). It's chemically similar enough to petroleum diesel that many engines can run on blends — common blends are B5 (5% biodiesel), B20 (20% biodiesel), and B100 (pure biodiesel). Learn more about What is biodiesel.

So what's the point? Biodiesel replaces part or all of fossil-derived diesel, which reduces reliance on crude oil and shifts emissions toward a fuel with lower net greenhouse gas emissions over its lifecycle, depending on feedstock and production methods.

How biodiesel is produced (simple)

Basic steps: collect feedstock, remove impurities, react with alcohol and a catalyst, separate glycerin, and refine the biodiesel. It's straightforward, but quality control matters — contaminants cause engine issues. From what I've seen, small producers sometimes cut corners, which is why supplier vetting is essential.

How does biodiesel affect the environment and public health?

Short answer: biodiesel generally cuts particulate matter, carbon monoxide, and unburned hydrocarbons compared with petroleum diesel, which translates into fewer respiratory problems in exposed communities. There's also a lifecycle climate benefit — in many cases emissions are lower because the carbon in biodiesel comes from recent biological growth, not geologic carbon.

But it's not perfect. Nitrogen oxides (NOx) can increase slightly with some blends, and feedstock sourcing matters a lot (more on that below). The health gains are tangible: fewer soot particles means fewer asthma attacks, fewer ER visits, and better long-term lung function for people near heavy-traffic corridors. I've seen municipal studies that link cleaner fuels to measurable drops in asthma-related ambulance calls — the difference was clear during a seasonal pilot program in one city last winter.

Is biodiesel a sustainable clean energy solution?

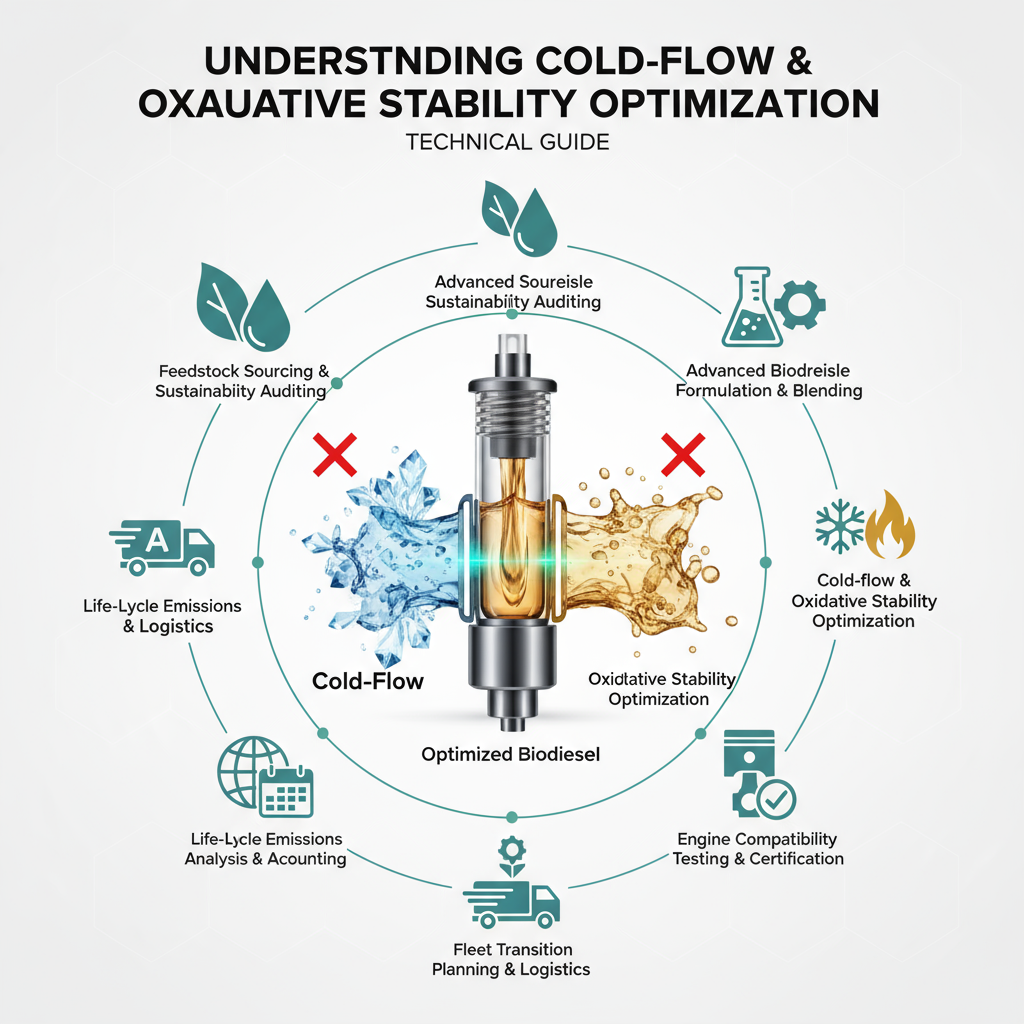

Yes, biodiesel can be a sustainable part of a clean energy mix — if you choose the right feedstocks and maintain rigorous lifecycle accounting. Sustainability hinges on three things: feedstock, production emissions, and land use impacts. For example, used cooking oil and waste fats score high on sustainability metrics because they repurpose waste and avoid land-use change.

Compare biodiesel to other clean energy options: electric trucks are great, but grid emissions and charging infrastructure are limiting factors for long-haul operations today. Biodiesel is practical now — it uses existing infrastructure and can reduce greenhouse gases and pollution today, rather than years from now. It's like choosing between a bicycle and a hybrid car when you need to haul freight; both have roles.

What are the environmental drawbacks and risks?

There are several, and you should know them up front:

- Feedstock risk - Growing palm oil on converted forests causes huge emissions and biodiversity loss. Avoid that. Look instead for certified waste-based or non-deforestation sources.

- NOx emissions - Some blends raise NOx a bit, which affects ozone formation. Engine calibration and additive strategies can mitigate this.

- Cold-weather performance - Biodiesel can gel at low temperatures, so cold flow improvers or seasonal blending schedules may be needed.

- Quality variability - Not all biodiesel is equal. Impurities can clog filters and damage fuel systems.

So yeah, there are trade-offs. The trick is managing them with specifications, supplier audits, and pilot testing — not flipping a switch and hoping for the best.

How can biodiesel reduce air pollution and improve community health?

Biodiesel cuts soot and many combustion-related pollutants that are linked to heart and lung disease. Replacing 20% of a city's diesel with B20 can lead to measurable reductions in fine particulate matter in traffic corridors (that’s PM2.5), which is strongly associated with lower rates of asthma, COPD exacerbations, and premature mortality. And because biodiesel improves lubricity, engines sometimes run cleaner, which reduces maintenance-related leaks and spills — small things that add up.

Practical tip: pair fuel changes with monitoring. Install a small network of air sensors near depots and busy routes, run a 12-week baseline, convert a subset of vehicles to biodiesel, and compare. That's how you prove health impact and justify scale-up to stakeholders and regulators.

How do organizations adopt biodiesel without risking operations?

Start small. Run a pilot on 5 to 10 vehicles, pick predictable routes, and use a certified supplier. Check warranty guidance from engine manufacturers (many allow blends up to B20). Train maintenance staff on filter changes and fuel handling. Monitor fuel stability, and plan for seasonal blends in colder months.

If this feels overwhelming, our team can handle fuel sourcing, compatibility tests, and regulatory reporting — we run the pilot, measure outcomes, and give you a clear roll-out plan. No guesswork.

Frequently Asked Questions

Will biodiesel harm my engine?

Probably not, if you follow guidelines. Most manufacturers approve blends up to B20. The main risks are poor-quality fuel and older seals that react to biodiesel. Replace seals if needed, stick with tested suppliers, and change filters more frequently during the first 6,000 miles of conversion.

Does biodiesel really cut greenhouse gas emissions?

Yes, in many cases. Biodiesel can cut lifecycle greenhouse gas emissions by up to 50% for certain waste-based feedstocks, because the carbon was recently captured by plants. Watch out for feedstocks linked to land conversion, which can erase climate benefits.

Is biodiesel more expensive?

Upfront per-gallon cost can be similar or slightly higher than diesel, depending on local supply and policy incentives. But factor in health co-benefits, lower particulate-related maintenance, and potential carbon credits, and the net cost often becomes favorable. We help clients run a full cost-benefit model so you see the real numbers.

How do I choose a biodiesel supplier?

Look for certification (ASTM D6751 or equivalent), transparent feedstock sourcing, and quality-control testing. Ask for batch test results. Visit the production site if you can. If a price looks too good to be true, it probably is.

Can biodiesel be part of net-zero planning?

Yes, but treat it as one tool among many. Biodiesel can bridge gaps while you electrify fleets and decarbonize the grid. For immediate air-quality and short-term emissions wins, biodiesel is practical and scalable.

Want help figuring out whether biodiesel fits your fleet or facility? We run feasibility studies, manage pilots, and prepare procurement and compliance documentation. Contact us and we’ll map a clear path forward — quick wins first, long-term strategy next.